The Apsynth team investigates the formation of lignins in plant cell-walls and their reactivity upon lignocellulosic biomass processing.

Thanks to its knowledge of lignin structural variability and of the molecular mechanisms involved in the conversion of phenolic compounds, the team holds a strategic position in international collaborative projects aiming at designing new bio-based ingredients.

Biological Question

Biological Question

Lignins are phenolic polymers exhibiting numerous functionalities, as well as high versatility based on their reactivity and the possibility to incorporate a wide range of phenolic structures through the polymerization processes (Vanholme et al 2012). Researches aiming at understanding and exploiting these characteristics have emerged at international level over these last decades, with particular emphasis on the lignin bioengineering in plants and subsequent lignin use as industrial bio-based source of molecules for materials formulation.

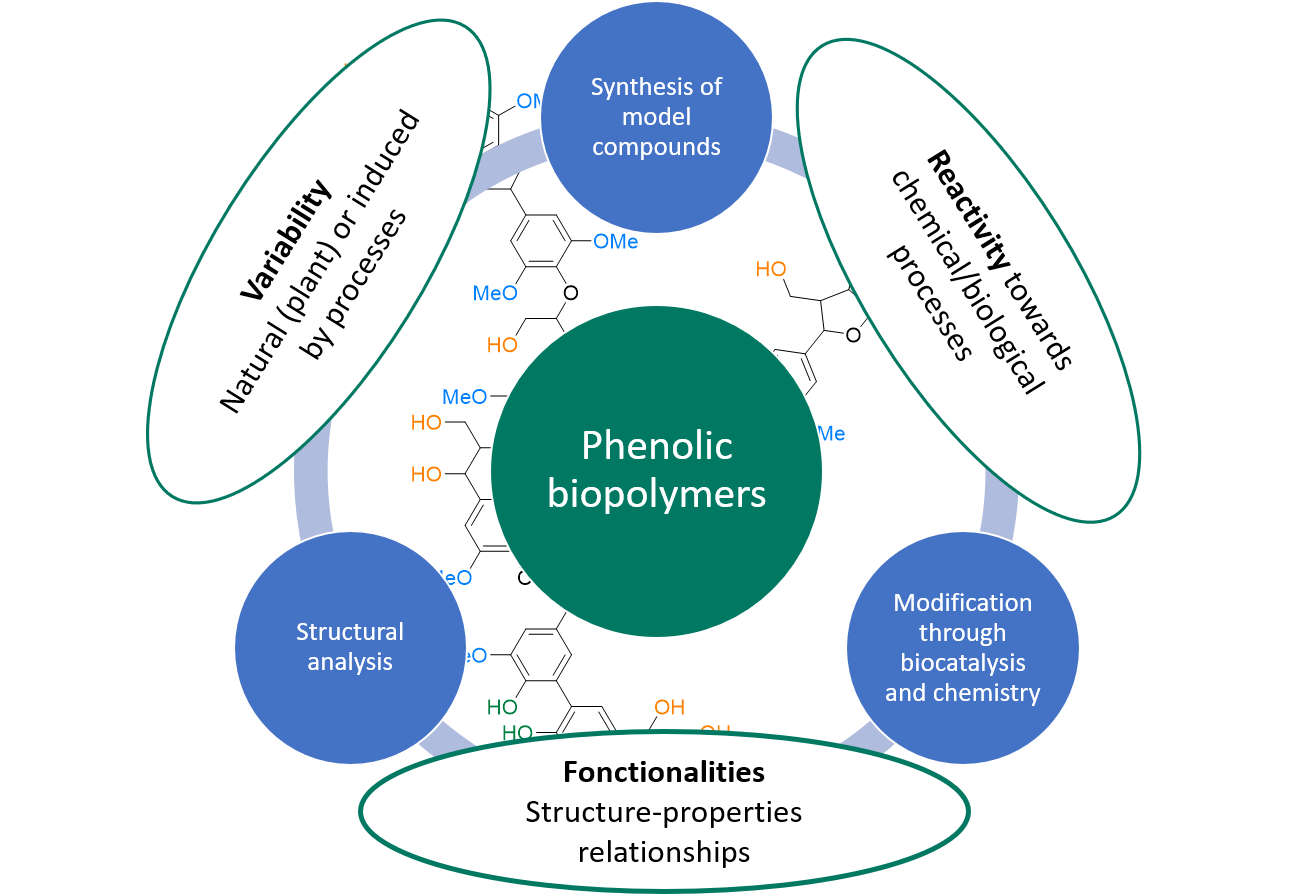

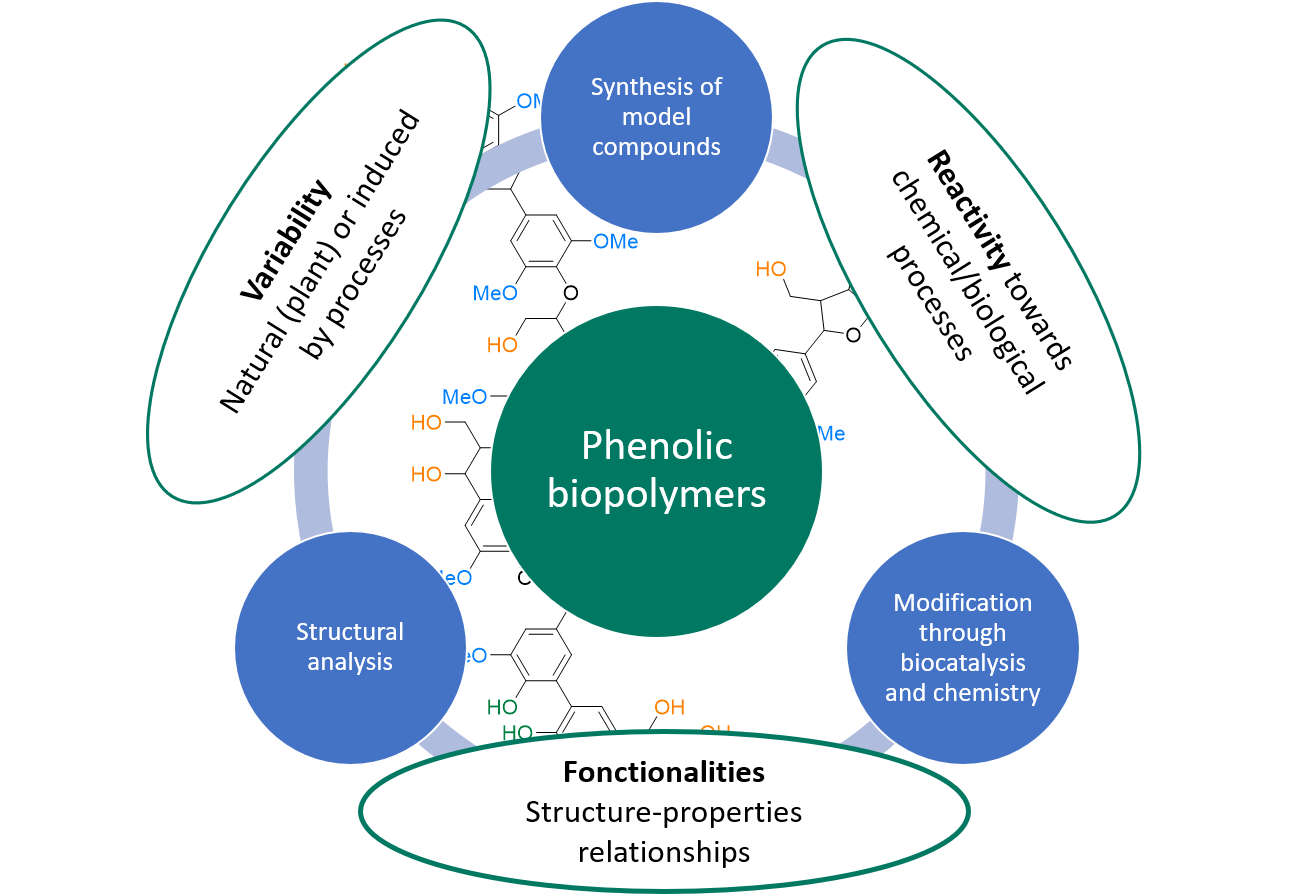

In this context, the Apsynth team explores lignin structural variability and use potentialities, from plant cell-wall to end-formulated materials, with a main focus on the following research questions:

• How do natural factors and delignification processes impact lignin's structure?

• What are the mechanisms governing the reactivity of lignins during chemical and biological conversion processes?

• What is the relationship between lignin's structure and functionalities?

In this context, the Apsynth team explores lignin structural variability and use potentialities, from plant cell-wall to end-formulated materials, with a main focus on the following research questions:

• How do natural factors and delignification processes impact lignin's structure?

• What are the mechanisms governing the reactivity of lignins during chemical and biological conversion processes?

• What is the relationship between lignin's structure and functionalities?

Models, tools and methods

To address these questions, the Apsynth team implements a multi-disciplinary approach involving structural analysis, synthesis of model compounds, and chemical or biocatalytic modification of phenolic biomolecules.

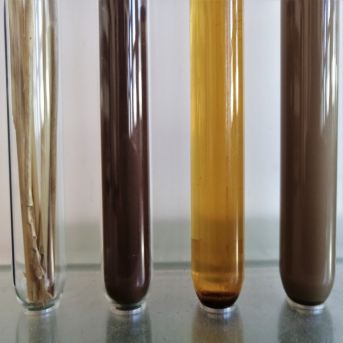

It studies and exploits feedstocks mainly from plant of agronomic and industrial interest (miscanthus, corn, camelina, poplar, eucalyptus, etc.), as well as coproducts from the lignocellulosic biorefinery (lignins from paper-making processes, lignocellulosic co-products from bioethanol production).

It studies and exploits feedstocks mainly from plant of agronomic and industrial interest (miscanthus, corn, camelina, poplar, eucalyptus, etc.), as well as coproducts from the lignocellulosic biorefinery (lignins from paper-making processes, lignocellulosic co-products from bioethanol production).

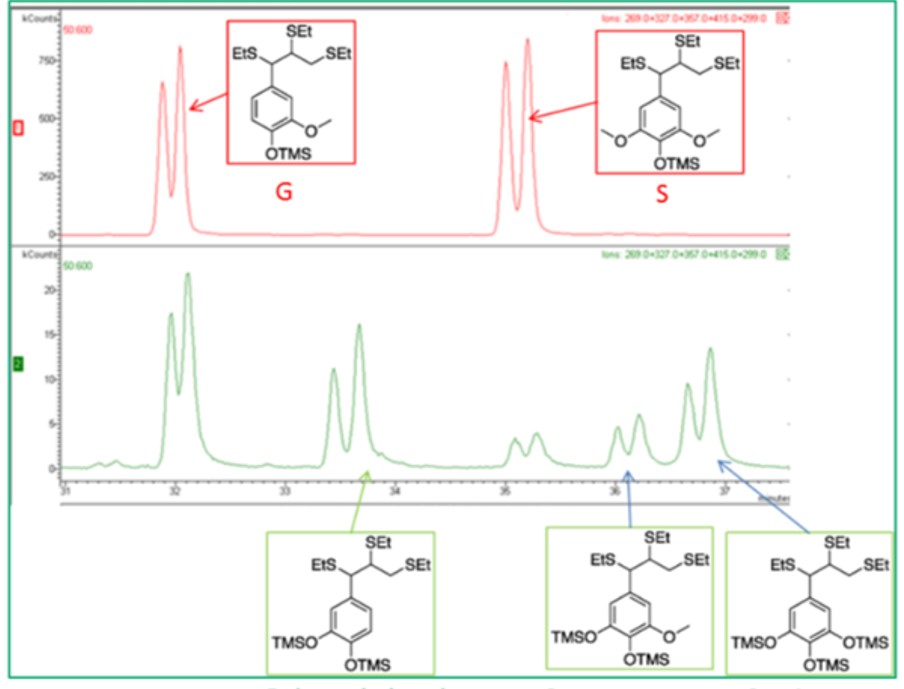

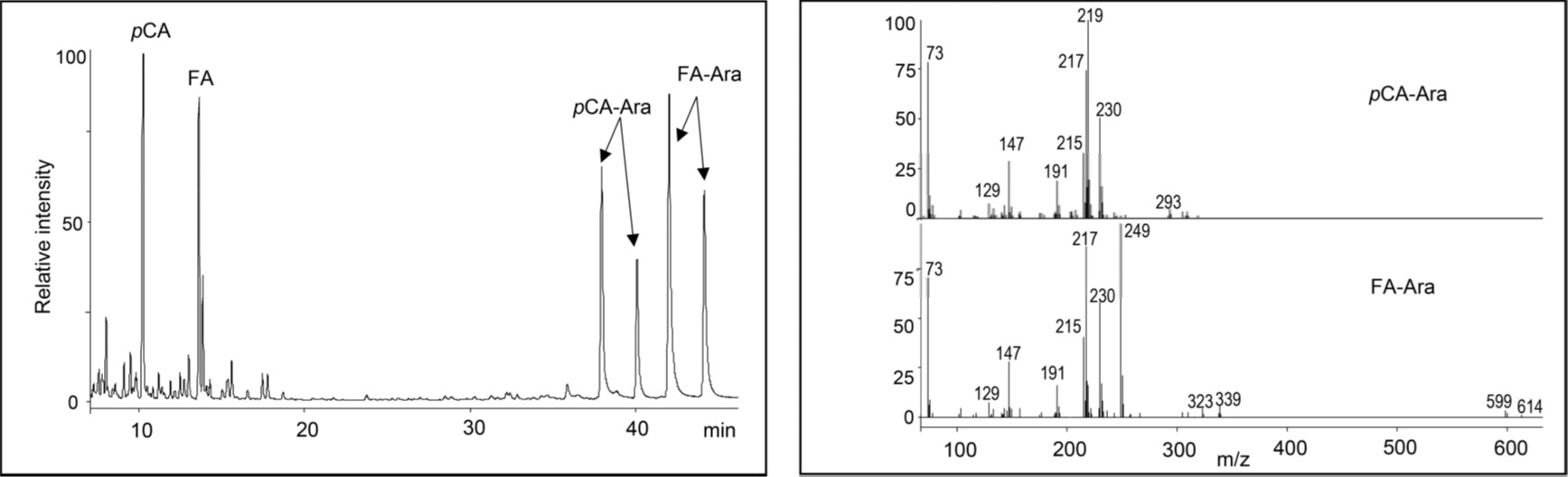

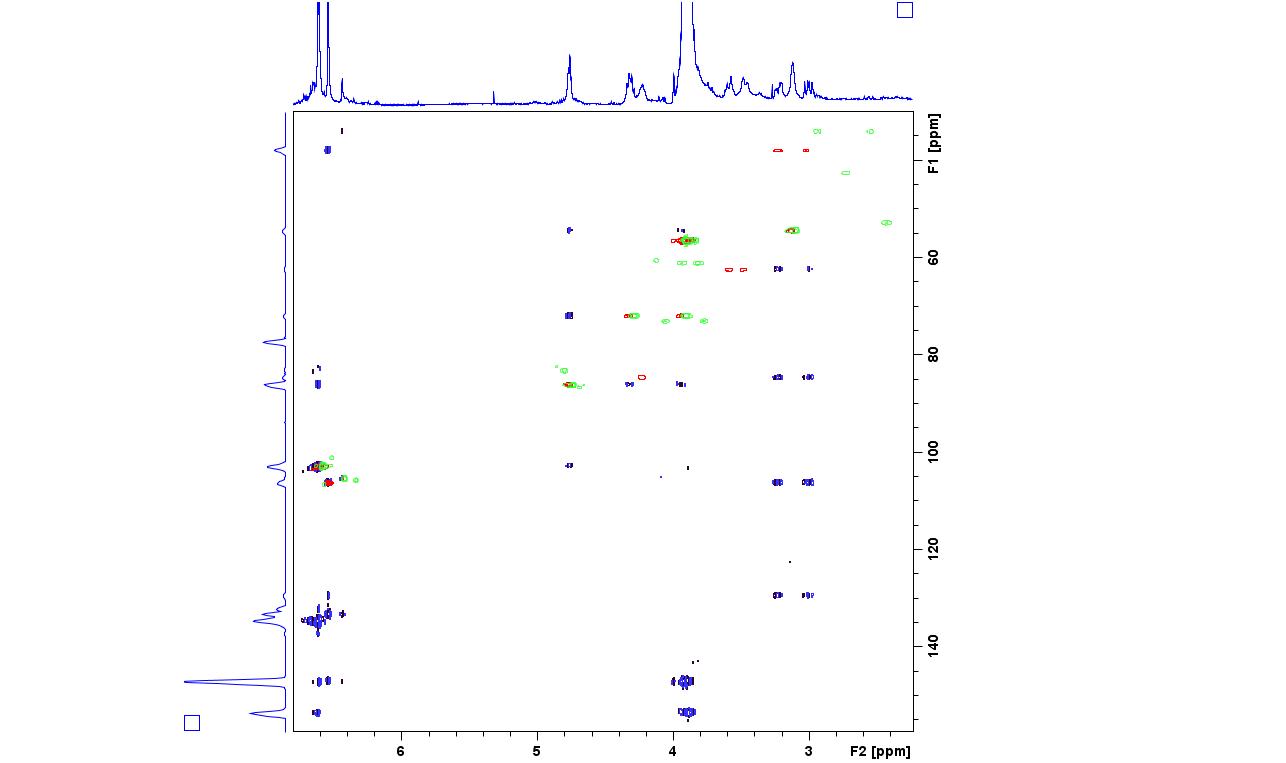

The comprehensive structural investigation of these materials is performed thanks to the complementarity of various analytical methods developed in the team in collaboration with the « Observatoire du végétal » platform:

nuclear magnetic resonance, chromatography, mass spectrometry, pyrolysis coupled with gaz phase chromatography, analysis of products from selective deconstruction.

nuclear magnetic resonance, chromatography, mass spectrometry, pyrolysis coupled with gaz phase chromatography, analysis of products from selective deconstruction.

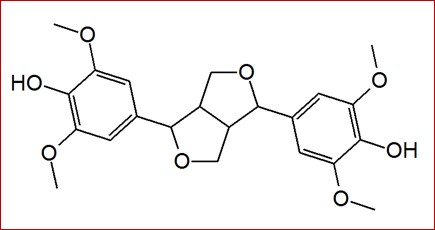

In order to facilitate the elucidation of mechanisms and the establishment of structure-property relationships, some lignin models with controled structure, high purity and solubility are synthetized and implemented in vitro.

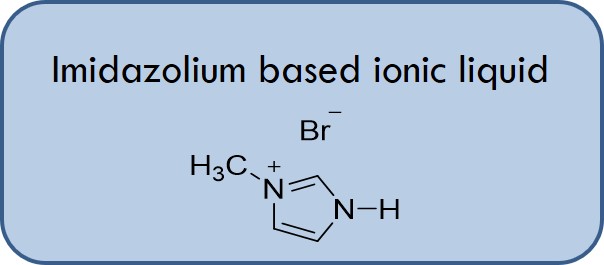

Lignin reactivity and deconstruction are investigated using biocatalysis (oxido-reductases and lipases) and selective chemical reactions (ionic liquids and bio-based organic solvents) meeting some green chemistry requirements. Other routes, like bioconversions (insects, fungi, bacteria) are explored in the framework of partnerships.

Societal and economical impacts

The Apsynth team takes part to knowledge transfer through the coordination of higher education training programmes in biotechnologies and bioeconomy : AgroParisTech engineer curriculum « Bioraffinerie – Chimie verte » (equivalent M1-M2) and DA Biotech (equivalent M2); Université Paris-Saclay Erasmus+ Bioceb (M1-M2). http://www.bioceb.eu/

More over, by taking part to public-private partnerships (3BCar Institute, Bio-Based Industry Joint-Undertaking, ERA CoBioTech programme) it contributes to the transfer of scientific knowledge from academic research to industry (biotech, chemical, cosmetic, and plastic sectors) and to the dissemination of technical innovation towards socio-economic actors.

Through the H2020 BBI JU Zelcor project « Zero-waste ligno-cellulosic biorefineries by integrated lignin valorisation », the team has contributed to the development of new value-chains using biorefinery recalcitrant residues (lignins and humins) as raw materials. http://zelcor.eu/

Through the H2020 BBI JU Zelcor project « Zero-waste ligno-cellulosic biorefineries by integrated lignin valorisation », the team has contributed to the development of new value-chains using biorefinery recalcitrant residues (lignins and humins) as raw materials. http://zelcor.eu/

The team has experience of collaboration with private partners, in particular in the framework of PhD fellowhips, with a resulting portfolio of 8 accepted patents.

Scientific popularization :

Conference at the ESPCI : https://www.canal-u.tv/video/espci_paristech/quand_le_bois_se_substitue_au_petrole.12678

Conference at the Academy of Agriculture : https://www.academie-agriculture.fr/actualites/academie/seance/academie/lignines

Conference at the ESPCI : https://www.canal-u.tv/video/espci_paristech/quand_le_bois_se_substitue_au_petrole.12678

Conference at the Academy of Agriculture : https://www.academie-agriculture.fr/actualites/academie/seance/academie/lignines

The Apsynth team has taken part to the COST Action LignoCOST dedicated to the sustainable valorisation of lignins. https://lignocost.eu/

Leader:

Stéphanie Baumberger